Compact Excavator

Versatile Engine Options: Customers can select from three premium single-cylinder engine models: Runtong, Briggs & Stratton, and Koop. This diverse lineup not only caters to varied functional needs but also fully aligns with the technical specifications and regulatory requirements of the European and American markets.

1-Ton Compact Design for Maximum Agility: With a 1-ton weight profile, the equipment boasts outstanding maneuverability. It is specifically engineered for easy operation in confined spaces, making it the ideal choice for garden maintenance, indoor projects, and small-scale job sites where larger machinery cannot access.

Full Compliance with Global Environmental Standards: The equipment fully meets the stringent emission requirements of Euro V and EPA standards. This ensures a smooth, hassle-free certification process for entry into European and U.S. markets, eliminating any potential compliance risks and supporting sustainable operational practices.

The Z10 1-Ton Mini Crawler Excavator redefines compact efficiency, tailored for tight spaces like small construction sites, residential gardens and agricultural farms. Equipped with trusted engines, a swing boom (for extended reach) and 1750mm digging depth, it handles light-to-moderate excavation with robust performance and flexibility.

Ideal for homeowners, small farmers and contractors, it balances power and practicality—plus reliable after-sales support to minimize downtime. For long-term value, it offers low maintenance costs (reducing overhead), a compact lightweight build (easy transport via small trailers) and consistent reliability.

Built for global markets, the Z10 stands out with zero-tail swing (safer, unobstructed tight-space use), customizable exterior and full Euro V/EPA compliance—ensuring smooth certification in Europe and North America, making it a high-value choice.

Key Features

Dependable Mechanical Controls: Features intuitive, streamlined settings that lower failure risks. With easy maintenance and a quick learning curve, it’s perfect for both new operators and experienced pros—no complex training needed.

1650mm Maximum Digging Depth: Hits 1650mm (5.6ft) deep, handling small-scale tasks like trench digging and foundation prep with effortless efficiency.

Molded Full-Body Construction: Mold-formed design ensures a sleek look, precise finishing, and boosted durability—elevating both visual appeal and overall product quality.

Inverted Boom for Wider Reach: The inverted boom expands horizontal and vertical operating ranges, outperforming standard mini excavators in tight or deep workspaces.

Free Swing Boom Included: Comes with a complimentary swing boom (no extra cost), enabling flexible 360° operation in confined areas without repositioning the machine.

Zero-Tail Swing Design: Removes rear overhang to avoid collisions in tight spots, maximizing usable space on job sites.

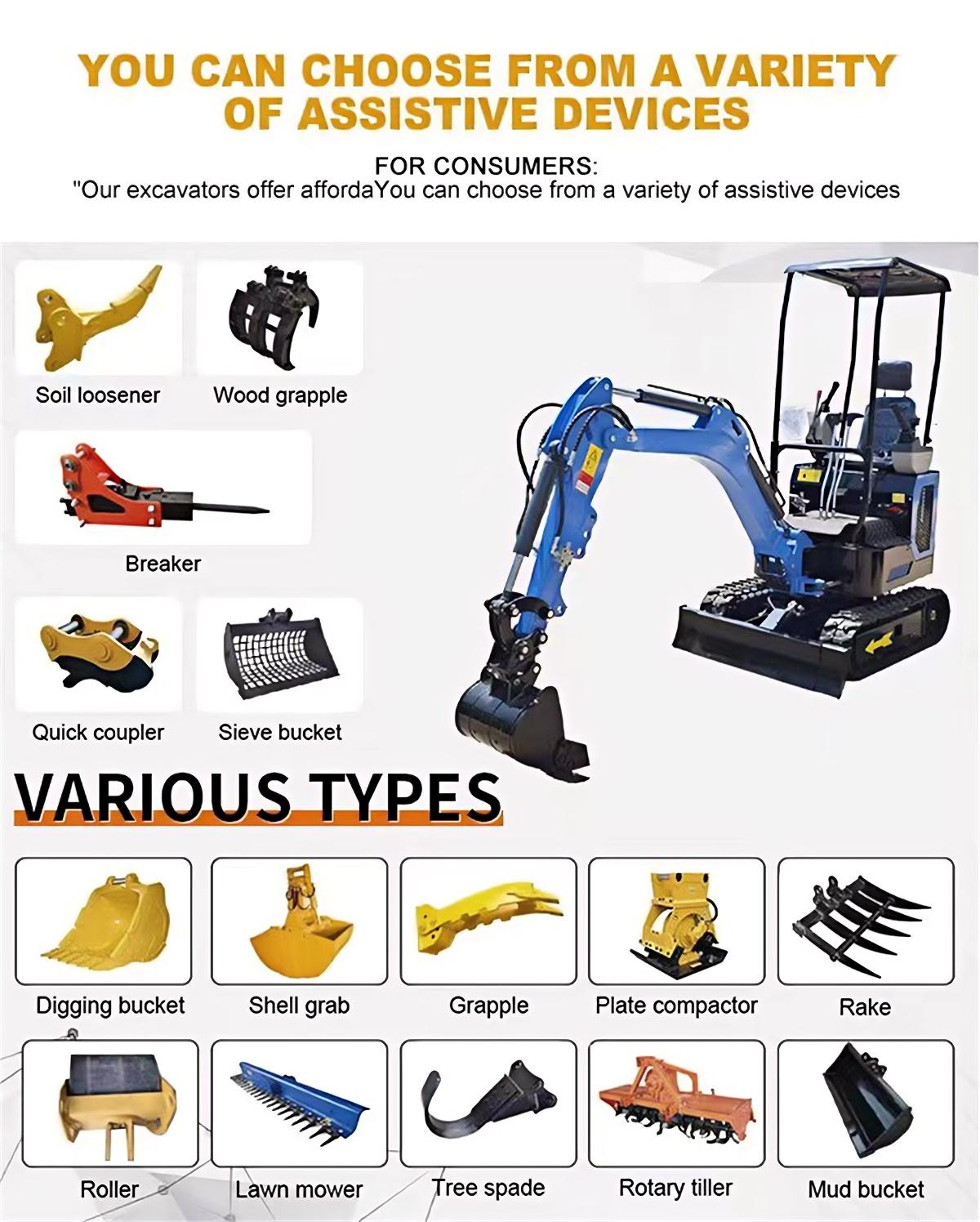

Multi-Attachment Compatibility: Works with breakers, grapples, augers, and more—turning the unit into a multi-functional tool for digging, demolition, lifting, and other tasks.

Product Parameters

Specifications | |

Engine Model | KD192FC-1 |

Emission standard | KD192FC-1/Briggs &Stratton |

Power/rpm | 7kw(3000)/10.07kw(3600) |

Emission | EURO5/EPA4 |

Bucket capacity(m³) | 0.025 |

Machine size | |

Dimension Length*Width*Height(mm) | 2950*1030*1600 |

With cabin height(mm) | _ |

With cabin wooden box size(mm) | 2500*1030*2300mm |

Operating Weight | 850KG |

Working range | |

Max. Digging Height(mm) | 2600 |

Max. Dumping Height(mm) | 1750 |

Max. Digging Depth(mm) | 1750 |

Ground length(mm) | 1220 |

Product Details

Product Accessories

Market-Tailored Engineering for Global Use

We don’t just build mini excavators—we design them for your specific market. Whether it’s complying with EU’s Euro V emission standards, matching North America’s EPA regulations, or optimizing machine size for tight Asian urban job sites, our R&D team ensures every unit fits local usage needs (from residential garden digging to small-scale construction). No more “one-size-fits-all” headaches—your customers get equipment that works seamlessly where they are.

Rigorous Quality Control for Long-Term Reliability

Understanding overseas clients hate costly downtime, we subject every mini excavator to 12+ quality checks (from engine load testing to boom durability trials) before shipment. We use globally sourced, wear-resistant parts (e.g., Briggs & Stratton engines, high-grade steel booms) to ensure machines stand up to frequent use—whether it’s daily trench digging for contractors or regular farm maintenance. Your customers get a tool they can trust, and you get fewer after-sales issues.

Fast Support & Flexible Logistics for Smooth Business

We know overseas shipping and after-sales can be stressful. That’s why we offer 24/7 English-speaking technical support (so your team or customers get answers fast), stock common spare parts in key global warehouses (reducing wait times for repairs), and partner with reliable logistics providers to deliver machines on schedule. Whether you need a small batch for a local dealer or a bulk order for a regional distributor, we adapt to your timeline—keeping your business running smoothly.