Mini Trackhoe Excavators

Space-Adaptive Performance:Conquer the most challenging work areas with the Z1-ton compact excavator. Engineered to operate efficiently in narrow passages, indoor renovations and dense urban settings, it overcomes traditional equipment limitations—transforming previously inaccessible residential and light commercial projects into viable opportunities.

Unified Functional System:Redefine your equipment efficiency with an integrated platform that instantly adapts buckets, breakers and augers for diverse tasks—from precision trenching and structural demolition to detailed landscaping.

Cost-Optimized Operation:Achieve enhanced financial performance through advanced fuel efficiency, reduced maintenance needs and simplified transport protocols. Documented reductions in daily operational costs empower contractors and dedicated DIY users to improve profit margins while meeting the evolving demands of budget-aware global clients—establishing a sustainable foundation for continued business growth.

Precision Engineering for Space-Constrained Applications:Mini Trackhoe Excavators Meticulously crafted for optimal performance in confined environments—including community gardens, residential properties, and compact orchards—this mini excavator combines rugged power systems with an advanced swing boom and 2000mm excavation depth. It enhances efficiency in essential operations from garden bed preparation to utility trenching, eliminating the need for supplementary equipment. Decrease operational costs, win additional local contracts, and address the industry gap where "standard machinery underperforms in specialized small-scale applications." Our solution-driven engineering delivers custom-designed answers for spatially limited working conditions.

User-Oriented Operation & Complete Support Ecosystem:Blending substantial digging capability with compact proportions and easy transport features, this model emphasizes straightforward operation and simplified maintenance. Supported by responsive technical assistance, prolonged service intervals, and effortless trailering, it helps homeowners reduce running costs, increases output for agricultural and contracting uses, and builds confidence for novice operators—all enabled by ergonomic design principles and comprehensive lifecycle support services.

Internationally Certified, Space-Safe Architecture:Incorporating a zero-tail swing mechanism for secure operation in tight urban locations and interior renovations, alongside full Euro V and EPA certification, this equipment facilitates rapid regulatory clearance across European and North American markets. It enables cross-border contractors and local DIY users to overcome "certification barriers" and "spatial restriction issues," while accessing specialized global market segments—validating its internationally compliant, market-adaptive engineering philosophy.

Key Features

Compact Mobility Solution:With a svelte 1-ton weight and streamlined chassis design, it readily enters garden spaces, rear patios, and constrained urban work zones—surpassing the "conventional equipment access limitation." Secure challenging projects such as backyard transformations, strengthen your regional market standing, and rapidly grow specialized service capacities.

Pre-Certified Compliance:Pre-verified against Euro V and EPA emission standards, it enters regulated European and North American markets without compliance obstacles. Avoid bureaucratic holdups and customs clearance problems, minimize market entry costs in premium areas, and accelerate investment returns.

Unified Excavation Capability:The 2000mm working depth manages varied tasks from utility network installation and tree planting to landscape development—removing requirements for multiple specialized machines. Lower initial capital expenditure, appeal to budget-minded customers, and improve project success ratios through integrated operational flexibility.

Maintenance Efficiency Design:A logically configured engine compartment enables quick fluid evaluation and part replacement—shortening maintenance periods and decreasing total ownership expenses. Benefit from minimized operational interruptions, optimize equipment utilization rates, and achieve enhanced daily productivity.

Collision Prevention Engineering:Featuring no rear projection, it substantially diminishes impact risks with building interiors, perimeter boundaries, and worksite obstructions. Ideal for interior refurbishment and confined exterior projects, it reduces liability exposure, enhances your safety reputation, and promotes client loyalty—completely addressing spatial safety considerations.

Product Parameters

SPECIFICATION | |

Operating weight | 900kg |

Bucket capacity | 0.03m³ |

Bucket width | 400mm |

Fuel tank capacity | 7.5L |

Engine | koop192/Briggs 25T/Runtong 25T |

Max. Grade ability | 30° |

| Bucket digging force | 12KN |

| Maximum tractive force | 12KN |

| MAIN DIMENSION | |

Track length | 1220mm |

Upper chassis ground clearance | 370mm |

Counter weight turning radius | 805mm |

Transportation length | 2970 |

| Total height | 2250 |

| Total height | 950mm |

OPERATING RANGE | |

Max. digging radius | 3100mm |

Max. digging depth | 2000mm |

Max. digging height | 2430mm |

Max. dumping height | 1800mm |

| Maximum vertical digging depth | 1950 |

| Minimum turning radius | 1470mm |

| Maximum Lift Of Dozer blade | 140mm |

Product Details

Advanced Frame Engineering:The 1-ton high-strength steel chassis navigates narrow passages, landscaped environments, and rural routes with accuracy—handling space-sensitive projects including hardscape construction and farm maintenance. Overcome traditional "large-equipment access limitations," expand geographical service reach, and secure high-value clients in developing sectors like urban greenspace restoration.

Impact Avoidance Technology:Designed to prevent contact with structural components, boundary markers, and interior fixtures, it significantly reduces costly collision incidents. Execute interior upgrades and compact-site developments with assurance—increasing client contentment and building lasting professional alliances.

Rapid Attachment Switching:Transition between buckets, breakers, and augers within seconds using a tool-free connection system—substantially reducing reconfiguration time between excavation, demolition, and planting activities. Eliminate workflow inefficiencies, handle increased daily project volumes, and simultaneously improve both operational output and earnings.

High-Performance Boom Assembly:The strengthened, specially treated boom structure sustains consistent 2000mm digging capacity for demanding utility projects and deep planting needs. It resists normal component wear, prevents profit-affecting downtime, delivers reliable operation under strenuous conditions, and reduces ongoing maintenance costs.

Product Accessories

Region-Specific Configuration:Custom-developed for European (Euro V aligned), American (EPA certified), and Asian operational settings—incorporating market-suited dimensional adjustments—it conforms to local emission regulations, safety standards, and unique operational requirements including Asia's spatially constrained worksites. Resolve "regional adaptation challenges," strengthen customer commitment, and enable smooth international market access—demonstrating our globally informed, locally customized engineering approach.

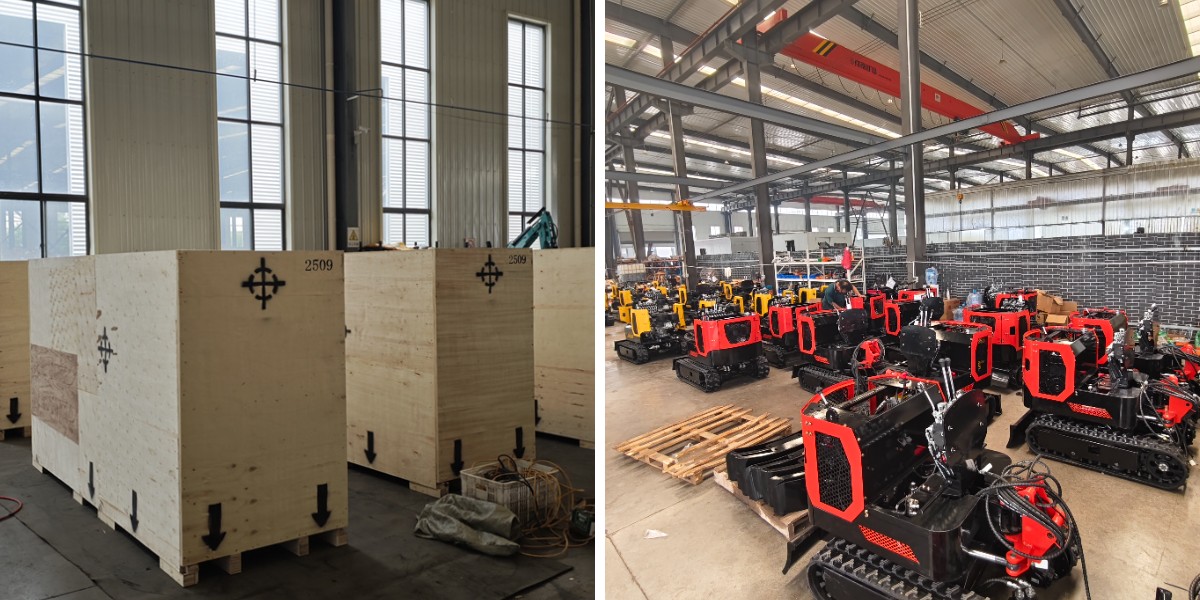

Comprehensive Quality Verification:Executing 12+ stage pre-delivery inspection procedures targeting drivetrain reliability and structural strength—supplemented with premium wear-resistant components—it maximizes operational uptime and reduces unexpected breakdowns. Decrease post-purchase service needs, manage financial risks from equipment failures, and support steady business growth through methodical quality control systems.

Integrated Global Support Network:24/7 multilingual technical support, accelerated international parts distribution to North American agricultural districts and European metropolitan zones, and guaranteed delivery for both individual and volume orders ensure uninterrupted worldwide operation. Overcome transnational service limitations, maintain continuous equipment performance, and establish durable client partnerships through a fully synchronized global support and logistics framework.